Liquid Painting, Conversion coating & Plating Services

316-542-0405

38628 W. 15th Street South, Cheney KS

Please drag & drop 3 more SECTION elements to below this section. If you enable sections 6 and 7, you must drag and drop 5 more SECTION elements.

Zinc Plating

Albers Finishing Solutions offers a variety of surface finishing, including zinc plating. Zinc is the workhorse of the commercial finishing industry. Highly decorative and inexpensive, it is reasonable in corrosion resistance. Major industries include lawn and garden, agricultural, automotive, hardware, recreational and more.

Why Plating

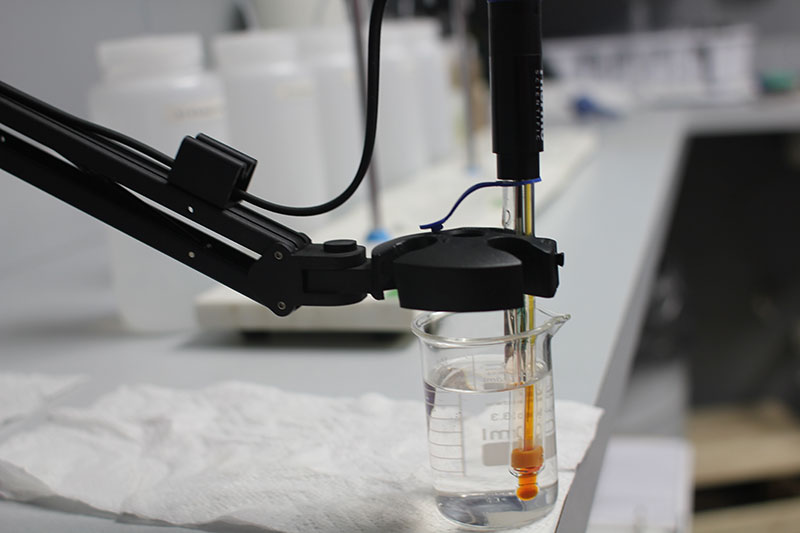

Plating Process

|

Typically, this is how a zinc-plating process works:

|

Plating Quality

|

Our experienced in-house lab technicians and process operators are able to identify and control many other factors that affect the results when plating with zinc that include:

● Correct positioning of the anode and cathode ● Substrate surface condition ● Agitation of the bath (or lack thereof) ● Use of additives such as surfactants and brighteners ● Concentration of hydrogen ions ● Duration of actual plating time ● Degree of filtration of the zinc plating bath ● Efficiency of the rinsing operation ● Amount of harmful pollutants/contaminants that may be in the plating bath |